Natural Gas Recovery Process. Raw natural gas needs to be treated to meet pipeline and liquefaction specifications. Cryogenic processes are the most economical method for breaking natural gas down into its constituent components. Higher Recovery with Less Energy Designed to be used in natural gas or shale gas applications the patented CRYO-PLUS process recovers more ethane and heavier components with less energy required than traditional liquid recovery processes. This chapter discusses the natural gas liquids recovery.

Linde has designed and produced modular gas processing plants worldwide for over forty years. We deliver completely pre-engineered modularized. These heavier hydrocarbon liquids commonly referred to as natural gas liquids NGLs include ethane propane butanes and natural gasoline condensate. Natural Gas Liquids Recovery A subset of NGL liquefied petroleum gas LPG focuses on propane and butane. The value of natural gas liquids such as ethane and propane is increasing due to growing global demand for petrochemical feedstock heating and power. The existing process involves a.

The section in question involves the combustion of the effluent fuel from the liquefaction process to produce usable work that drives the overall process.

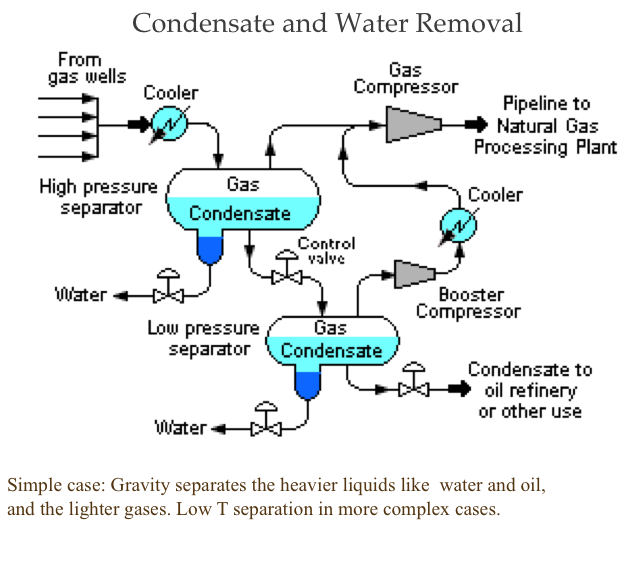

Natural Gas Liquids Recovery A subset of NGL liquefied petroleum gas LPG focuses on propane and butane. NGL Recovery Separation Fractionation and Treatment of Natural Gas Liquids In addition to these processes it is often necessary to install scrubbers and heaters at or near the wellhead. Recovery of NGL components in gas not only may be required for. Many of the innovations we have developed like the use of plate-fin exchangers and packings in cryogenic columns remain today as standard designs in the industry. The scrubbers remove sand and other large-particle impurities. Turboexpansion processes are the most prevalent type of recovery processes.