Isopropanol Process Flow Diagram. The entire system used for this process consists of a feedstock stream a recycle stream a pump a heater the reactor and two coolers as illustrated in Graphic 1. Both of the methods involve the hydzation of Propylene. The blue labels are product designations. Base Process Block Diagram The base case study deals with the production of acetone from isopropyl alcohol by the.

Base Process Block Diagram The base case study deals with the production of acetone from isopropyl alcohol by the. The pharmaceutical industry is the process of catalytic dehydrogenation of isopropyl alcohol due to the high purity of the product. Both of the methods involve the hydzation of Propylene. The blue labels are product designations. After separation the dilute acetic acid would be concentrated and recycled. In the first process step the 9160 lbs.

Under steady state operation stream 37 consists of 171 lbs.

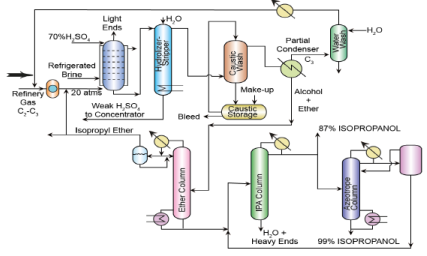

The blue labels are product designations. The feed is heated vaporized and superheated in aheat. The reactor effluent is a liquid phase. Public holidays and company maintenance time. The production of acetone is 3482 kmolh from a process feed of 3482 kmolh of isopropanol representing an overall conversion of approximate ly 100. A flow diagram of the reaction section and the fractionation section of a contemporary process for the production of isopropyl alcohol is presented at page 173 of the November 1981 issue of Hydrocarbon Processing.