How To Test An Ultrasonic Transducer. The transducer is typically separated from the test object by a couplant such as oil or by water as in immersion testing. The temperature constrains the Piezo material types which can be used. Designing an Ultrasonic Transducer The first step in designing a transducer is to determine the temperature the device will see over its lifetime. Ultrasonic Transducers - Measurements and Horn Design.

The transducer is typically separated from the test object by a couplantsuch as oil or by water as in immersion testing. There are three main aspects to working with ultrasonic measurements. In this process this transducer measures the distance of the object not by the intensity of the sound. It is important to consider both the expected maximum transient temperature and the ongoing long-term use temperature. The transducer is typically separated from the test object by a couplant such as oil or by water as in immersion testing. Typical units are MHz for frequency analysis microseconds for waveform analysis and dB down from peak amplitude.

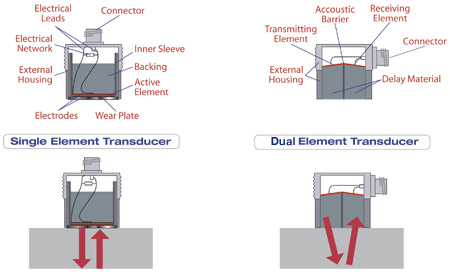

The high-frequency vibrations that are the basis of ultrasonic NDT commonly occur as either longitudinal waves particle motion parallel to wave direction or shear waves particl.

Ultrasonic Transducers - Measurements and Horn Design. You watch the oscilloscope signal as you sweep the transmitter frequency. Transducer waveform and spectrum analysis is done according to test conditions and definitions of ASTM E1065. Generating a tone at the resonant frequency of your transducer Receiving the tone through a band-pass filter at the resonant frequency of your transducer Measuring the time between the sending of the tone and the reception of the echo. Then connect an oscilloscope to the terminals of the transducer and check that its receiving the proper input. The temperature constrains the Piezo material types which can be used.